We love Occupational Health - Call and say hello - Mon - Fri 8.30am - 4.30pm

We love Occupational Health - Call and say hello - Mon - Fri 9am - 5pm

Blog Layout

Manual handling training myths & top tips

Introduction

Before I set out my 14 top tips, let’s deal with a number of myths that still abound concerning the physiology of the human spine and its application in the design of Manual Handling Training Courses:

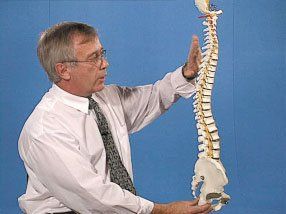

The spine has adapted or has been designed (depending on your point of view) for the upright posture – one example of this is the change in size that occurs between the bones (vertebrae) that make up your back. Look at the picture above and you can see that the vertebrae at the top of our spines are much smaller than those at the bottom of our spines. This is because the bones at the top of the spine do not carry as much weight as those at the bottom and so do not have to be as large as the ones at the bottom that have to carry the whole weight of the trunk. The contrast in size between the vertebrae at the top and bottom of the spine is quite unique to humans.

Myth 2: The inter-vertebral discs act as shock absorbers – Wrong!

The anatomical construction of inter-vertebral discs is such that they are simply physically too stiff to absorb shock. The real shock absorbers for the spine are actually the large muscles at the front of our thighs – the quadriceps muscles.

Myth 3: You should lift with a hollow in your low back – Wrong!

We now know that there is a better load distribution in the discs of the spine if the low back is maintained in a flat or slightly flexed position than in a hollow position.

Myth 4: The load to be lifted should be as light as possible – Wrong!

When the tissues that make up our spines are loaded optimally, they respond by strengthening. If you do not use your back, it will weaken!

Myth 5: You should avoid twisting movements – Wrong!

Twisting movements carried out to the extreme of range should be avoided – but avoiding twisting altogether weakens the muscles that control this movement, making the spine more vulnerable.

14 Top Tips for Manual Handling Training

1. Before even thinking about training:

- Build management support

- Conduct a Manual Handling risk assessment

- Adopt a participatory ergonomics approach

2. Management support is crucial to success

- Needs visible commitment

- Managers need to be familiar with course content

- Suggest including managers in training session

3. Training should be part of an overall risk management programme, assessing:

- Task

- Load

- Working environment

- Individual capability

- Work organisation

- Build and maintain knowledge and skills (refresher courses)

- Discourage ‘tick box’ mentality, often just focusing on legal compliance

- Consider ‘cascade’ training

5. Training should be provided:

- At induction

- As a planned on-going process

- Charisma

- Credibility

- Experience

- Breadth of knowledge

- Ability to engage and communicate

- Those commissioning training should establish that trainers are appropriately qualified and competent.

- Onus is on the trainer to demonstrate their competence.

- Experience of training is insufficient of itself.

- Level of awareness

- Literacy/language skills

- Physical fitness

- Establish if employees have pre-existing injuries

- Make it relevant

- Use a mixed approach to learning

- Consider different learning styles

- Include a practical element – ideally task specific practice

- Equip workers to risk assess for themselves

- In relation to training, ideally 8 – 12 people

- Too many people can lead to distractions

- Too few people can result in poorer discussion quality

- A half day, up to one day

- Include regular breaks – this aids concentration

- Formal refresher components

- At least every 12 months

- Why Manual Handling matters

- Statutory requirements

- Anatomy and physiology

- Care of the back

- Handling principles

- Hands on experience

- Risk assessing situations

- Dealing with problems

- Evidence that physical fitness reduces injury

- General strength training better than training specific muscle groups

- Improved worker fitness also beneficial for morale

COPE's Occupational Health Blog

By barbara.fisher

•

29 Jun, 2023

Occupational Health Advisors (OHA) - Lancashire

09 Mar, 2022

Are you looking for work as an Associate Occupational Health Advisor?

By barbara.fisher

•

23 Feb, 2020

COPE is a UK wide occupational health provider with a network of Occupational Health Physicians across the UK.

We are seeking to expand our network of physicians to work on a self-employed basis with COPE. If you are interested in partnering with COPE, please do contact us to find out more by mailing hr@copeohs.com

COPE is a company that values people from all backgrounds. We welcome and nurture diversity in our business and are proud of our open and inclusive culture.